Description:

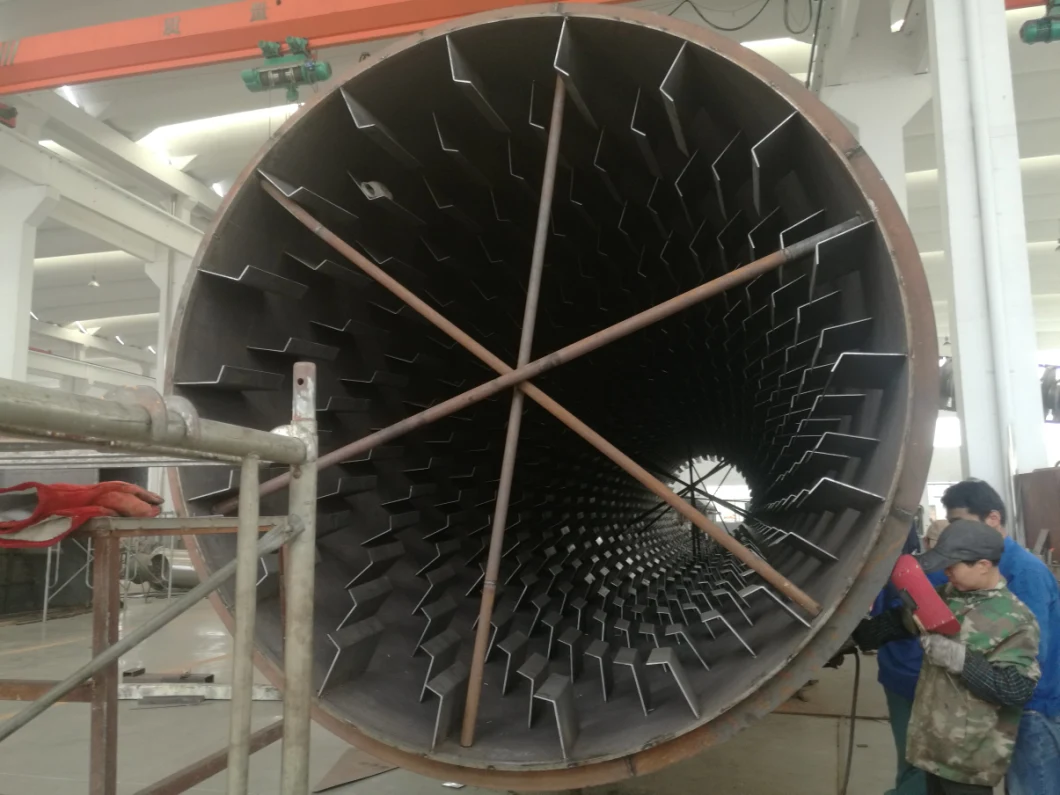

Description:After the wet materials are fed into the rotary drum dryer, they are stirred by the shoveling plates and uniformly distributed in the cylinder. Then the materials fully contact with cocurrent of counter-current hot air, thus accelerating heat transfer and mass transfer. During the drying process, the materials under the effect of titled shoveling plates and hot air can move to the discharge valve at the other side of the cylinder dryer and finally be discharged.

Application:

1. HG rotary drum dryer is designed to dry large particles, such as ore, blast furnace slag, coal, metal powder, phosphate fertilizer and ammonium sulfate in the chemical, mining, metallurgical and other industries.

2. This drying equipment can be used for drying special powdery and granular materials, including HP foaming agent, vinasse slag, light calcium carbonate, activated clay, magnetic powder, graphite and dregs.

3. HG cylinder dryer can dry the materials that require low temperature and continuous drying.

Features:

1. HG rotary drum dryer possesses high level of mechanization and large production capacity.

2. This drying equipment has strong applicability to the material properties.

3. This drying machine can designed with multilayer inner sleeve structure. So the staying time of the material can be longer and the production capacity can be greatly enhanced.

4. Our rotary cylinder dryer has the advantages of stable operation, low operating cost and good drying uniformity.

Parameters of HG Rotary Drum Dryer:

| Model | Production Capacity (t/h) | Cylinder Speed (r/min) | Motor Power (kw) | Installation Angle (°) | Discharging Material Humility |

| HG1.0 | 0.5-1.2 | 0.6-6 | 4 | 3-5 | ≤1.5% |

| HG1.2 | 1.5-3 | 5.5 | |||

| HG1.5 | 3-5.5 | 15 | |||

| HG1.8 | 5-6.5 | 18.5 | |||

| HG2.2 | 7-12 | 22 | |||

| HG2.4 | 9-15 | 30 | |||

| HG3.0 | 16 | 55 |

Drying Cases of Rotary Drum Dryer:

| Type | Direct Heating Cocurrent | Direct Heating Cocurrent | Direct Heating Counter-Current | Direct Heating Counter-Current | Composite Heating | Composite Heating |

| Material Category | Ore | HP foaming agent | Blast furnace slag | Ammonium sulfate | Phosphate fertilizer | Coal |

| Handling Capacity (kg/h) | 1000 | 466 | 15000 | 20000 | 5000 | 1000 |

| Initial Water Content (%) | 30 | 13 | 6 | 1.5 | 6.5 | 30 |

| Final Water Content (%) | 15 | 0.3 | 1 | 0.1 | 0.1 | 15 |

| Average Particle Size (mm) | 6.5 | 0.05 | 4.7 | 0.5-1.7 | 5 | 6.5 |

| Material Accumulation Weight (kg/m2) | 770 | 800 | 1890 | 1100 | 750 | 770 |

| Hot Air Volume (kg/h) | 39000 | 5400 | 10750 | 9800 | 16000 | 39000 |

| Inlet Air Temperature (ºC) | 600 | 165 | 500 | 180 | 570 | 600 |

| Outlet Air Temperature (ºC) | 150 | 42 | 100 | 70 | 75 | 150 |

| Heating Method | Gas | Steam, electrical heating | Heavy oil | Coal hot air furnace | Heavy oil | Heavy oil |

| Loading Coefficient (%) | 6.3 | 7 | 7.5 | 18 | ||

| Rotating Speed (rpm) | 4 | 4 | 3.5 | 3 | 2 | 4 |

| Gradient (mm) | 0.04 | 0.005 | 0.03 | 0.05 | 0.043 | 0.04 |

| Number of Shoveling Plate | 12 | 24 | 12 | 22 | Outside 8, inside 16 | 6, 12 |

| Dryer Diameter (m) | 2.0 | 1.5 | 2 | 2.3 | Outer cylinder 2 inner cylinder 0.84 | Outer cylinder2.4 inner cylinder 0.95 |

| Dryer Length (m) | 20 | 12 | 17 | 15 | 16 | 2.0 |

| Driving Power (kw) | 22 | 7.5 | 15 | 11 | 15 | 22 |

Company introduction:

Changzhou No.2 Drying Equipment Factory Co.,Ltd is an old drying enterprise which has 23 years drying history. We have got several patents in different dryers. We have much experience in different drying area. Now it holds more than 100 sets of equipment. The company has more than 100 staff and workers, including 15 engineers, with annual value of production more than thirty-eight million RMB.We attach importance to advanced technology, and have cooperated positively with universities and colleges to develop new products by using new technics. We have continuously developed several key and high-tech products with advanced technology both from domestic and abroad.During the past ten continuous years, the company has been appraised as enterprise with high reputation on contract and credit.Bases on the principle of factualism, innovation and mutual benefit, the enterprise is looking forward to creating resplendence with personages from all circles together.

customers from all of the world