5HKB grain dryer

- grain dryer

- For drying: rice, paddy, maize, wheat, sesame, rapeseed, cocoa, coffee, bean, chickpea, quinoa, chia, garlic, onion, seed and many other agricultural products etc.

- Multiple choice fuel type: coal, wood, diesel, gas LPG or NG, biomass such as rice husk, pressed straw bricks, corn cob, coconut shell, wood chip, coffee hull.

Features of grain dryer

1. High automation (automatic monitor over hot air, grain and moisture, automatic failure alarm); Automatic circulating, discharging and shutdown system;

2. Multi functional furnace (one furnace is designed for many purposes. It uses heating sources such as coal, firewood, crop straw and husk, etc.);

3. Lowest cost (for every 12 tons rice to be reduced 5% moisture, it costs 78.0RMB for burning coal, and 37.5RMB for burning husk ).

4. Drying cereal shiny bright, no paste, cracking rate is lower than the national standard corn standard 4%. Drying the finished rice, bursting rate below 2%, cracking rate of less than 4%, the color showed a natural state, Eliminate grain pollution.

5. 15 years of grain drying technology precipitation

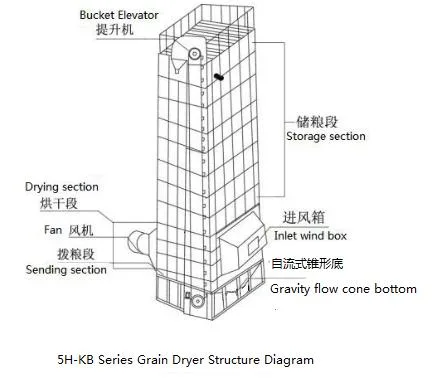

Structure of grain dryer

Stove of grain dryer

It consists of 3 sectors of fire-proof wall, 2 layer brick of every fire-proof wall

Advantage: reasonable design can avoid open flame. So it run steadily, safely and have long use-life.

Can be fueled by coal, wood, rice husk, diesel, etc.

Electric control cabinet of grain dryer

Fully automatic control system, using imported PLC control system to accurately control drying temperature and moisture content. Easy to operate with touch screen operation, engineers provide employee training.

Drying section of grain dryer

It adopts stainless steel pentagonal galvanized stainless steel structure to avoid direct contact between grain and hot air, prevent grain pollution, uniform drying and good drying effect, bright color after drying, and firm structure for easy maintenance.

Product DescriptionMobile grain drying machine is a new design multifunction grain dryer which adopts heating method of low temputure, it can keep original color and taste, low cracked ratio.

Mobile grain drying machine includes dryer tower, elevator, belt conveyor, electric control cabinet, stove, moisture content detector.

Application

Mobile grain drying machine is suitable for efficient drying all cereals, rice/paddy, grains, soybean, beans, maize, coffee bean, wheat, barely, millets, sunflower seed, soybean, oil seeds, etc.

It is also suitable to all kinds of farm and rice processing industry, such as rice mill.

Characteristics

We can meet your any special requirements, such as: Add insulation. Use special heat source(biomass, rice husk, diesel, coal, electric, steam, etc.), special designed, Special accessories, etc.

1. Speedy Drying Maize

2. User friendly & Easy Maintenance.

3. High Durability

4. Fast installation.

5. Multiple safety devices.

HEATING FURNACE

1)Automatic input and automatic outpur by high pressure

2)According to temperature demands, paddy husks and air volume are controlled by automatic frequency conversion to save paddy hus and electricity power

3)High efficiency stainless steel tube good thermal conductivity

4)Exchange conduction with 9 times ,the highest thermal conductivity

5)Automatic control temperature range +1 of hot and cold wind

Specifications

| Model | 5H-KB-15 | 5H-KB-20 | 5H-KB-35 | |

| Dryer type | Batch type recirculating | |||

| Capacity | 15 tons per batch | 20 tons per batch | 35 tons per batch | |

| Dryer Volume(m3) | 25 | 37.25 | 62.5 | |

| Overall weight(kg) | 5000 | 6000 | 9500 | |

| Overall Dimension(mm) | 2900*4050*11500 | 2900*4050*12200 | 3500*4400*13330 | |

| burner | Type | Indirect Type | ||

| Ignition method | Manual Ignition | |||

| Fuel consumption (kg/h) | ≤25(coal) 30-40(rice husk) | ≤25(coal) 30-50(rice husk) | ≤30(coal) 70-120(rice husk) | |

| Power(kw) | 8.7 | 9.4 | 13.65 | |

| Fuel | Biomass (rice husk, straw, wood chips), coal, diesel | |||

| Voltage | 380V, 50Hz, 3 phase (Can be customized) | |||

| Moisture Reduction per hour(%/h) | Rice/wheat:0.5-0.8 | Rice/wheat:0.5-1.2 | ||

No suitable model? It does not matter, our engineers can design the production line according to your requirements

10/25/30/50 tons per batch model, more information, pls contact us.