Square Bottom Kraft Shopping Paper Bag Machine with Double Layer

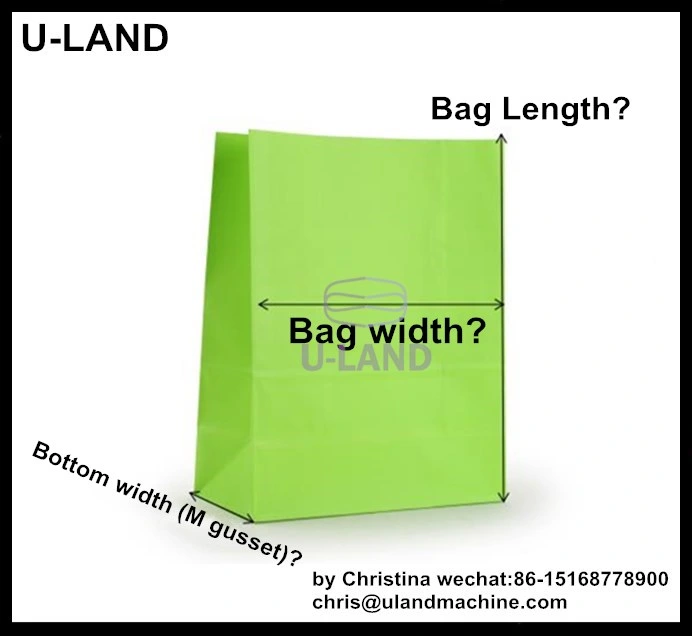

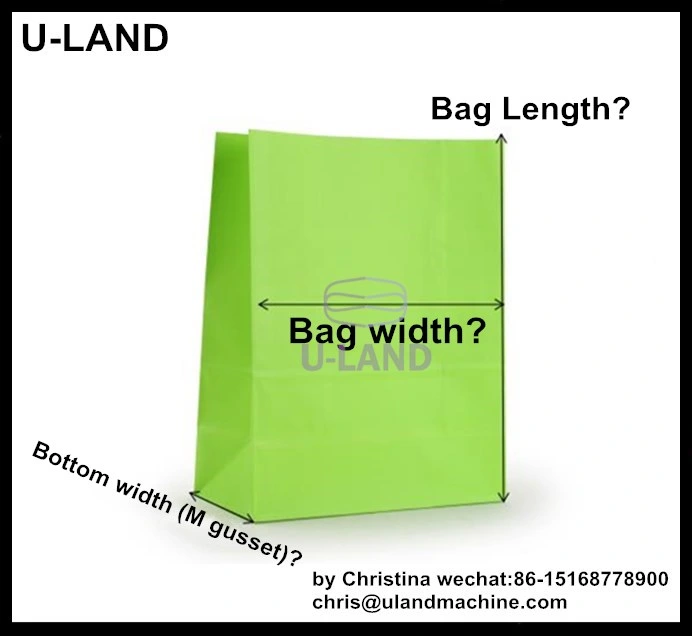

OUR SUGGESTION:

1)Your Min. and Max. Bag width ?

Bag length?

Bottom size(M gusset size?)

2)Which type of paper bag do you need it ?

if you need one machine from our,pls.let me know the above information,

then we will quote and offer you suitable right models with best price.

We are the most proferssional manufacturer who is producing paper bag making machine,

food paper bag machines,small-sized packed food paper bags machine series and printing machine,

slitting machine whole lines.

We have strong technical force and advanced equipments.and has won high respect of the clients.

Our products are well distributed to the countries and regions like Africa,Europe,America,middle east,south

east asia,and south america,hongkong,taiwan also.our paper bag machine are well accepted in the market.

Structural features:

1. Double-layer paper tape printing square bottom bag making machine is composed of unwinding device, printing device, forming device, receiving device (and some auxiliary equipment).

2. Introduced the touch screen man-machine interface, which is easy to modify and fine-tune. Alarm and working status can be displayed on the screen for easy operation and maintenance.

3. Equipped with Kunlun Tongtai company's PLC centralized control system, Germany SICK photoelectric correction, tracking accurate printing materials, minimize adjustment and preset time, and improve production efficiency.

4. Human-oriented safety protection, the entire house design, to ensure the safety of operators.

5. Inflatable hydraulic feeding system, chuck, hydraulic up/down system.

6. Automatic unwinding constant tension control, EPC network guide and inverter feeding system, motor, minimize the adjustment time of network alignment.

7. High-speed design to ensure success: production within the appropriate paper range, with a production capacity of 30-1580pcs/min or even higher. Increase unit production capacity and higher profits.

8. The original German Schneider Electric system ensures better stability and reliability, perfect after-sales service, and trouble-free for customers.

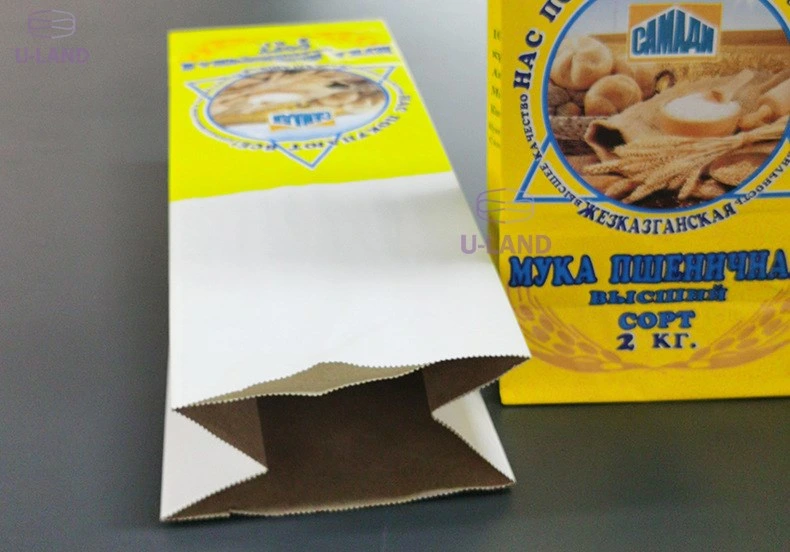

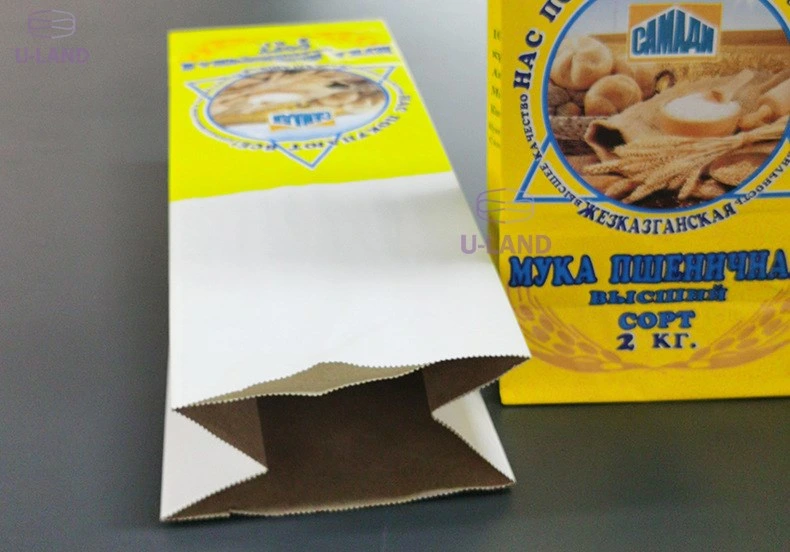

Products Show:

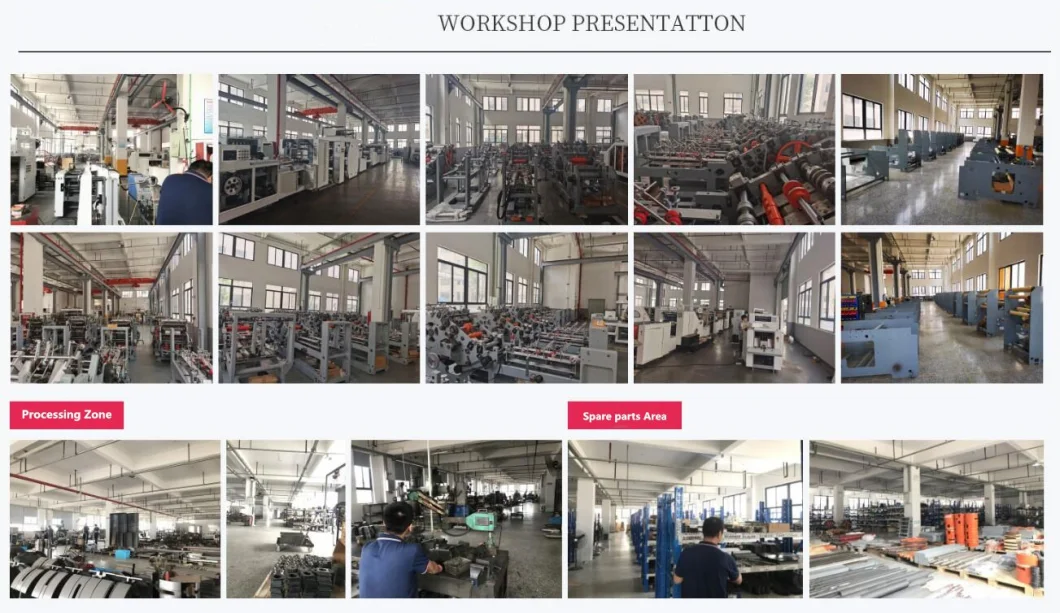

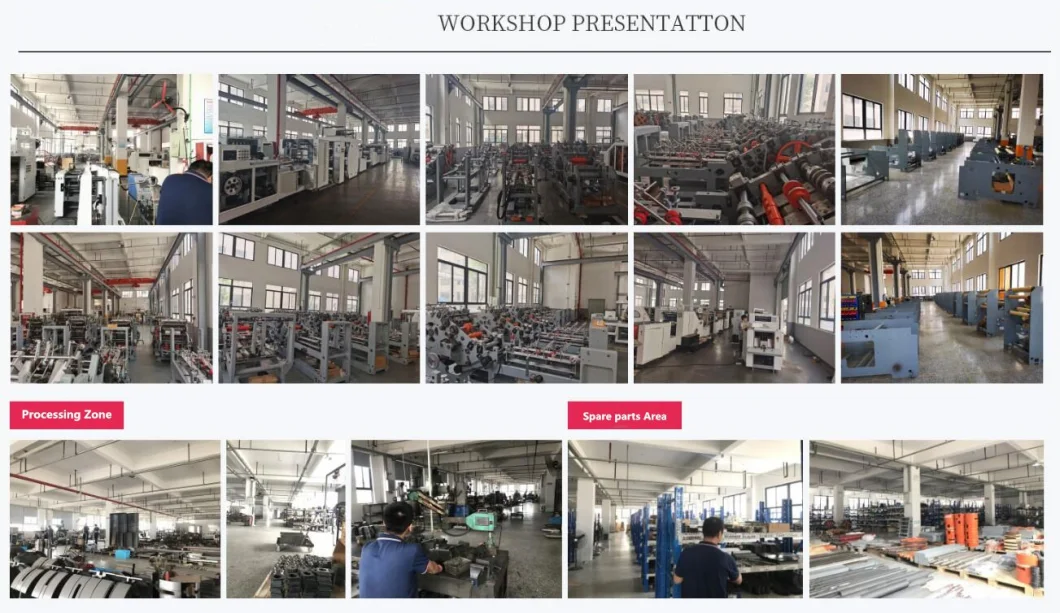

Mechanical display:

Technical parameter:

Shipment:

OUR SUGGESTION:

1)Your Min. and Max. Bag width ?

Bag length?

Bottom size(M gusset size?)

2)Which type of paper bag do you need it ?

if you need one machine from our,pls.let me know the above information,

then we will quote and offer you suitable right models with best price.

We are the most proferssional manufacturer who is producing paper bag making machine,

food paper bag machines,small-sized packed food paper bags machine series and printing machine,

slitting machine whole lines.

We have strong technical force and advanced equipments.and has won high respect of the clients.

Our products are well distributed to the countries and regions like Africa,Europe,America,middle east,south

east asia,and south america,hongkong,taiwan also.our paper bag machine are well accepted in the market.

Structural features:

1. Double-layer paper tape printing square bottom bag making machine is composed of unwinding device, printing device, forming device, receiving device (and some auxiliary equipment).

2. Introduced the touch screen man-machine interface, which is easy to modify and fine-tune. Alarm and working status can be displayed on the screen for easy operation and maintenance.

3. Equipped with Kunlun Tongtai company's PLC centralized control system, Germany SICK photoelectric correction, tracking accurate printing materials, minimize adjustment and preset time, and improve production efficiency.

4. Human-oriented safety protection, the entire house design, to ensure the safety of operators.

5. Inflatable hydraulic feeding system, chuck, hydraulic up/down system.

6. Automatic unwinding constant tension control, EPC network guide and inverter feeding system, motor, minimize the adjustment time of network alignment.

7. High-speed design to ensure success: production within the appropriate paper range, with a production capacity of 30-1580pcs/min or even higher. Increase unit production capacity and higher profits.

8. The original German Schneider Electric system ensures better stability and reliability, perfect after-sales service, and trouble-free for customers.

Products Show:

Mechanical display:

Technical parameter:

| model | UL-180 |

| Paper weight | 45-120gsm |

| Paper bag length | 190-370mm |

| Paper bag width | 80-180mm |

| Bottom width of bag | 50-100mm |

| Maximum unwinding diameter | 1400mm |

| Roll paper unwinding width | 600mm |

| Inner diameter of paper core | 76mm |

| Machine speed | 180pcs/min |

| Machine power | 10kw |

| Machine weight | 4500kg |

| Machine size | 7700*1700*2100mm |

Shipment: