1.Our Company Overview

*Founded more than 10,0000 machines are in operation worldwide, with more than 14 years of machines still running in China .

*After the appraisal by China Textile Machinery Association, the technical level of water jet looms produced by Haijia Machinery has reached the international advanced level.

*In 2018, 10,800 machines were sold, in 2019,more than 8000 sets were sold ,with a market share of 21.37%, ranking first .

*Adheres to the corporate mission of providing customers with competitive weaving solutions and services, and continues to create value for customers.

2.Our Machine Model

Water Jet Loom

HW3851; HW3873 ; HW861C; HW4008; HW4010; HW4012 HW5012; HW8010

Air Jet Loom

HA-N ; HA-9010

3.Machine Specification

4.Our workshop

*More than 40 imported precision processing CNC, 80% of the parts are our own processing, quality control.

*The painting workshop adopts the fully-automatic painting line and spraying

robot independently developed by the company, and uses the same electrophoresis

coating process as automobile production within 3-5years machine no rust.

*Wallboard/beating style/gear/bearing, all the important part all uses same supplier and same standard with TSUDOKOMA China.

5.The high quality product

*Two times running life than ordinary brand, higher speed, more 16% efficiency of comprehensive production

*One worker can operate at least 24 sets machine, save labor 33%

*less maintenance cost

6.Customer Representative

Our products are sold all over the world.We have a solid customer base in India, Pakistan, Malaysia, Mexico, Morocco, Guatemala, Indonesia, Bangladesh, Nepal, Vietnam, Egypt, Turkey and other countries.

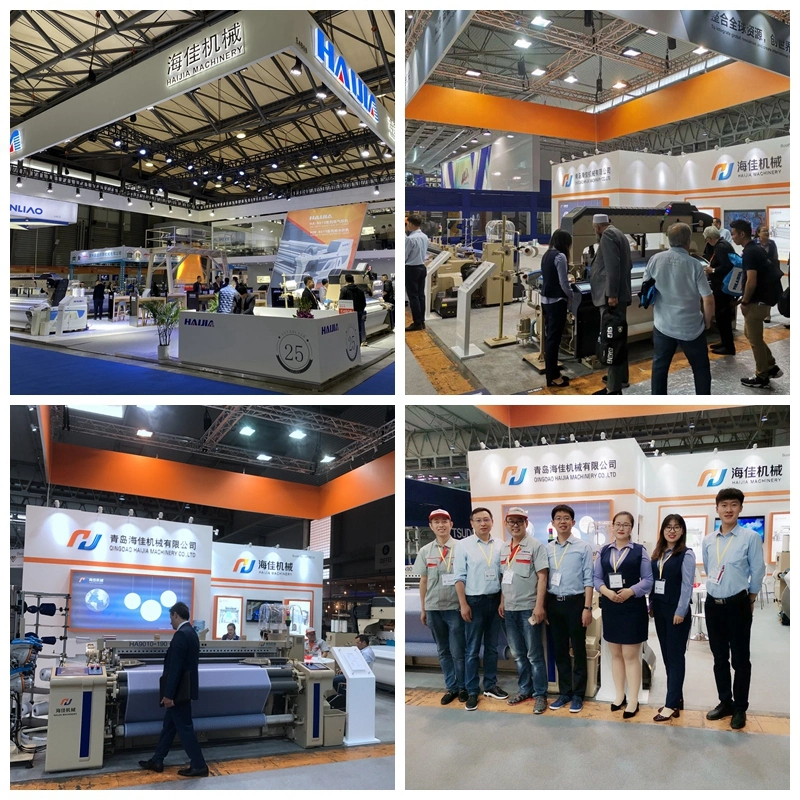

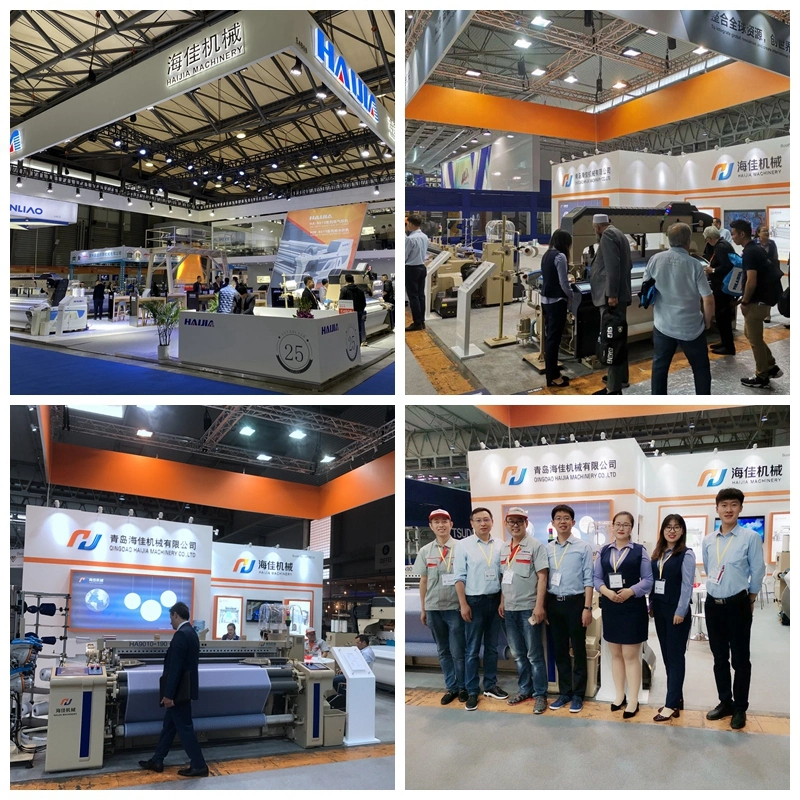

7.Exhibition Site

*Every year we go to various countries to participate in textile machinery exhibitions, to visit our local customers, organize various introduction activities, and invite customers to visit our factory.

8.Our service

1)Technical service

our company will provide best services to help you use our machine.As well,if you want to send your technician to our company to learn how to operate machines,we will very pround of it.

2)Quality Guarantee

We provide 12 months warranty.

3)Problem solving

We have professional engineers will deal with your problem at the first time.

In particular, we will arrange our engineers to go to your factory to debug the new machine until it runs well. In the early stage, we will also provide you with free services such as designing the layout of the factory and the layout of the water and electricity.

For any further information,just contact me on-line or mail me !

*Founded more than 10,0000 machines are in operation worldwide, with more than 14 years of machines still running in China .

*After the appraisal by China Textile Machinery Association, the technical level of water jet looms produced by Haijia Machinery has reached the international advanced level.

*In 2018, 10,800 machines were sold, in 2019,more than 8000 sets were sold ,with a market share of 21.37%, ranking first .

*Adheres to the corporate mission of providing customers with competitive weaving solutions and services, and continues to create value for customers.

2.Our Machine Model

Water Jet Loom

HW3851; HW3873 ; HW861C; HW4008; HW4010; HW4012 HW5012; HW8010

Air Jet Loom

HA-N ; HA-9010

3.Machine Specification

| Item | Standard specifications | option | |

| Reed space | Nominal(cm) | 150,170,190,210,230,260,280,320,340 360 | |

| Neck in(mm) | 0--600mm | ||

| Weaving scope | Weft Insertion Rate | 1400-2200M/min | |

| Filament | 8D-5000D | ||

| Weft selection | Single/Double /Three/Four Nozzle | ||

| Power | Super start motor, Direct drive Motor | ||

| The motor rating(KW) | 1.8, 2.2, 2.8, 3.0 , 3.7 ,4.0 , 4.2, 4.5 | ||

| Weft insertion | Main nozzle, deputy nozzle together, use special reed | tensile | |

| Auxiliary main nozzle | |||

| Deputy nozzle relay control | |||

| Shedding | Crank shedding | ||

| Upper cam shedding | |||

| Upper dobby shedding | |||

| Let off | Mechanical or Electronic | ||

| Variable dis dia(mm) | 800or 1000 | ||

| Take up | Mechanical or Electronic | ||

| The largest cloth diameter(mm) | φ520 | ||

| Weft density range | 7.1-80.3 pick//cm(18-204pick/inch) | ||

| Weaving length counting | Displayed on the keyboard display, with the function of scale parking | ||

| Beating-up | Crank type sley feet more beating -up mechanism | ||

| Four linkage beating-up | |||

| Measuring weft Storage | Electric drum weft | ||

| Leno | Planetary gear type | ||

| Cutter | Mechanical scissors | ||

| Stop device | Weft stop | Reflex detector | |

| Warp stop | 6 columns batching motion | ||

| Other | Wring side,yarn end processing broken parking | ||

| Fault display | Operating screen | ||

| 4 color indicator light display | |||

| Automation | The computer control system | ||

| Monitoring and self diagnosis function | |

4.Our workshop

*More than 40 imported precision processing CNC, 80% of the parts are our own processing, quality control.

*The painting workshop adopts the fully-automatic painting line and spraying

robot independently developed by the company, and uses the same electrophoresis

coating process as automobile production within 3-5years machine no rust.

*Wallboard/beating style/gear/bearing, all the important part all uses same supplier and same standard with TSUDOKOMA China.

5.The high quality product

*Two times running life than ordinary brand, higher speed, more 16% efficiency of comprehensive production

*One worker can operate at least 24 sets machine, save labor 33%

*less maintenance cost

6.Customer Representative

Our products are sold all over the world.We have a solid customer base in India, Pakistan, Malaysia, Mexico, Morocco, Guatemala, Indonesia, Bangladesh, Nepal, Vietnam, Egypt, Turkey and other countries.

7.Exhibition Site

*Every year we go to various countries to participate in textile machinery exhibitions, to visit our local customers, organize various introduction activities, and invite customers to visit our factory.

8.Our service

1)Technical service

our company will provide best services to help you use our machine.As well,if you want to send your technician to our company to learn how to operate machines,we will very pround of it.

2)Quality Guarantee

We provide 12 months warranty.

3)Problem solving

We have professional engineers will deal with your problem at the first time.

In particular, we will arrange our engineers to go to your factory to debug the new machine until it runs well. In the early stage, we will also provide you with free services such as designing the layout of the factory and the layout of the water and electricity.

For any further information,just contact me on-line or mail me !